Ron Garner 2025 Click any image to start a slide show

On top of the Morgan firewall there is a metal toolbox thingy that is used as a catch-all for the jack, tools, and whatnot. It probably originated as a stiffener to prevent flexing of the scuttle

Rainwater gets into it and runs under the rubber matt that sits on top of the firewall. On all older Morgans the firewall under the rubber matt rusts (often all the way through). I’ve been aware of this forever but never thought to do much more about it than to put goop under the rubber matt.

For several years I have been shipping my ’67 drophead “BENE” to Europe for extended tours. I relocated the battery on BENE from behind the seat to on top of the firewall (like a four seater). The rational being that after a transoceanic voyage the battery is often dead and having the battery under the bonnet makes it more convenient for dock workers etc. to jump it. But I also have “real” tools in the toolbox that I would prefer did not tempt theft. A cover closing the top of the toolbox seemed prudent. OH MY! That will also keep water out; a bonus! Now I make covers on all Morgans that I restore. It’s easy and has real benefit. I can think of many options so consider the following as suggestions. You may have another way to accomplish the same thing.

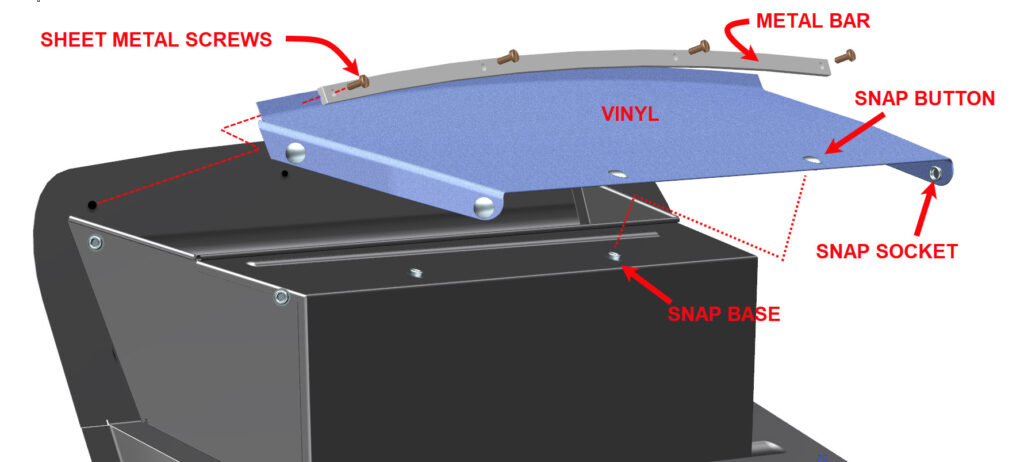

As I said, the process is pretty simple: 1. Make a strip of aluminum, steel, or even wood (provided it is stiff enough) and screw it to the firewall at the top of the toolbox. 2. Drill the toolbox for the snap bases. I pop-rivit two on each side and two on top. 3. Make a paper pattern: fold it under the metal strip, trace the toolbox extents. 4. Use the pattern to cut out a piece of vinyl with sufficient extra material for hems all around. Hems can be sewn if you have access to a sewing machine or just folded and glued. 5. Fit the vinyl under the metal strip, stretch it over the snaps, mark the snap locations, make a hole, and fit the snap buttons and sockets. Lastly install vinyl with some sealant behind the metal strip.

NOTE: Drophead Coupes have an access hole cut into the front face of the firewall. The bar for the toolbox cover must be curved to pass over it.